For background, I wrote about the original complaint here, and then a followup here, and then wrote about a farm visit here. Farm visit: I took the health department representative, two conservation district reps and my attorney, and we walked all over the farm and looked at anything they wanted to look at.

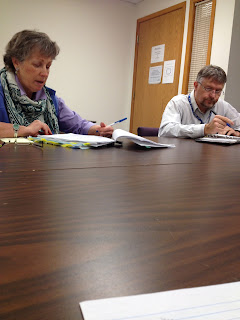

This is the view of my side of the table. Katherine is on the left, and Mike, her supervisor, is on the right, and we're talking about the complaint. Not shown is my attorney, who is sitting immediately to my right.

Solid waste on display in a supermarket

I think when I started my farm I had visions of growing things, and working with animals, and was a bit worried about flood season, and that it would be hard work. The hardest part of farming for me is the constant regulatory activity. Joel Salatin wrote a book entitled "Everything I want to do is illegal" and I have to say that I really, really agree with him. There is nothing that I can do that isn't regulated by someone.

Ok, So we're sitting at this table, and we're talking about what I feed my pigs. The health department doesn't like me feeding my pigs fruits and vegetables. They'd rather I switch to a commercial feed; mike, the fellow on the right, made that suggestion. If I fed a commercial feed, the health department would be just fine with me. No violation, no enforcement, done.

Ok. You're skeptical. I'm a little surprised too. So I ask a question. If I took a 50lb bag of pig feed, and poured it on the ground, would the health department object to that? No, says both Katherine and Mike. that'd be fine. Ok. If I took a ton (2,000lbs) of pig feed, and poured it on the ground, and the pigs ate it, would that be a problem? Again, no. Unanimous.

So I asked: "If I went to safeway, and I purchased an apple, and I took that apple and fed it to my pigs by throwing it on the ground, would you object to that?" No, they would not. " Ok, what if I got a 10lb sack of apples and dumped the apples on the ground. Would that be a violation of any law? " Yes.

One of these is not solid waste. Or is it?

What law would I be violating? "You would be improperly handling solid waste", says Katherine. Ok. I don't understand. When I purchase the apple from safeway, is that apple solid waste? No. Ok. I transport that apple in my car to my farm, and I feed the apple to the pig. Is that solid waste?

We have crossed the solid waste line. Or maybe not. No one knows.

"Mr. King, we'd like you to comply with the law. This discussion is getting us nowhere. We will not discuss this matter further."

Commercial pig feed is made out of mostly corn and soybean meal. It's processed vegetables. I can feed as much of that as I like, where ever I like, and it's all ok. I can throw processed vegetables on the ground. Is the health department paid by Cargill?

But apples are solid waste. Well, somehow they become solid waste. Somehow. But they can't tell me when, where or how they do.

Actual picture of the fruit I fed my pigs an hour after the meeting. I am thankful that there are only 2 apples in this picture.

Oh dear. There are three apples.

UPDATE: It's not just Washington State. Here's a story from Missouri about a fellow who was not allowed to feed vegetables raised on his own farm to his pigs. His blog entry about the situation.